About Us

Founded in 1977, SIN LING CO., LTD has grown into a global brass pipe fittings manufacturer and precision components supplier serving the automotive, hydraulic, pneumatic, and industrial fluid markets. Backed by decades of engineering experience, we provide reliable solutions under our well-recognized Plum Blossom® brand, trusted by OEMs and distributors worldwide.

✦ Global Manufacturer of Precision Fittings

SIN LING specializes in:

-

Brass and copper connectors

-

Hydraulic fittings and hydraulic hose fittings manufacturer capabilities

-

Pneumatic and air system fittings

-

OEM fittings and customized components in brass, steel, stainless steel, and aluminum

-

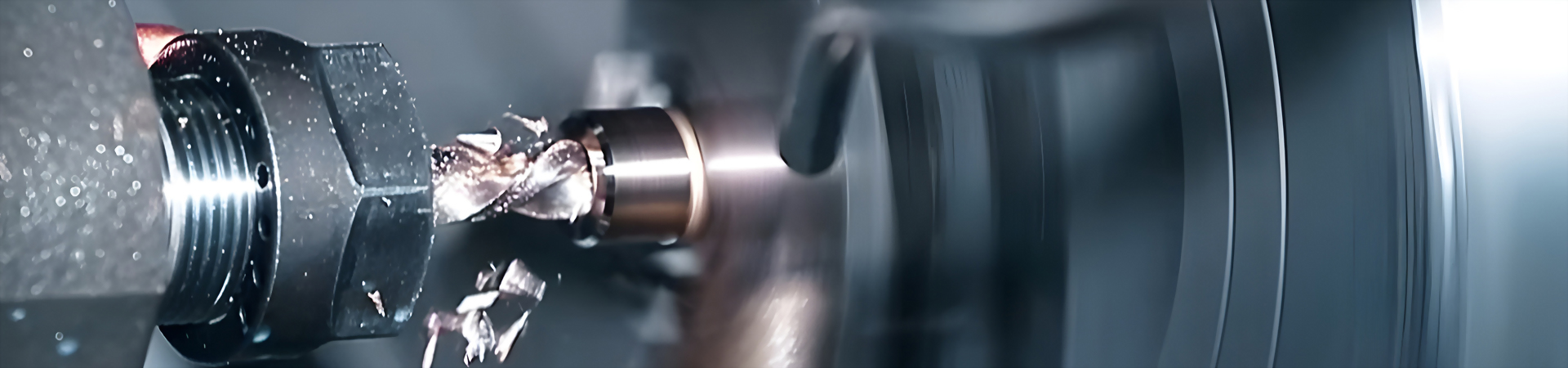

High-volume CNC production and advanced multi-axis machining services

With an annual output exceeding 10 million precision fittings, we support customers across commercial vehicles, industrial equipment, fluid control systems, and aftermarket distribution.

✔ Certified Quality & Compliance

Every SIN LING product is manufactured under strict quality control—from raw material inspection to final shipment. Our certifications include:

-

ISO 9001:2015 – Quality Management System

-

IATF 16949 – Automotive Quality

-

FMVSS 571.106 – DOT Air Brake Fittings Compliance

These certifications reinforce our dedication to producing dependable, safety-critical components for air brake, hydraulic, and pneumatic applications.

SGS IATF 16949:2016 Certification Details

The management system of SIN LING CO., LTD. has been assessed and certified by SGS as meeting the requirements of the IATF 16949:2016 standard.

Scope of Certification: Manufacture of various type fitting and connector for pipeline and brakeline use.

SGS IATF 16949:2016 Certification Details

The management system of SIN LING CO., LTD. has been assessed and certified by SGS as meeting the requirements of the IATF 16949:2016 standard.

Scope of Certification: Manufacture of various type fitting and connector for pipeline and brakeline use.

✦ A Leading Brand in Taiwan – Driven by Continuous Innovation

As one of Taiwan’s earliest manufacturers of copper and brass fittings, SIN LING continues to invest in R&D, automated machining, and advanced testing equipment to deliver stronger, safer, and more consistent products.

Our philosophy remains unchanged:

“SIN LING is synonymous with quality.”

This belief drives our engineering improvements, machining precision, and long-term customer partnerships.

✦ Your Trusted Partner for Global OEM Projects

Whether you require OEM fittings, DOT-certified air brake connectors, high-precision hydraulic parts, or a capable supplier offering multi-axis machining services, SIN LING is committed to supporting your next project with reliable quality, fast delivery, and engineering expertise.

⭐ About Us – FAQ

1. What industries does Sin Ling serve?

Sin Ling supplies precision fittings and machined components for automotive, commercial vehicles, pneumatic systems, hydraulic equipment, industrial machinery, fuel systems, and general fluid control markets. We are recognized globally as a trusted brass pipe fittings manufacturer and OEM supplier.

2. Does Sin Ling provide OEM or custom machining services?

Yes. Sin Ling offers full OEM fittings development, including design support, prototyping, custom materials, special geometries, and tailored packaging. We also provide advanced multi-axis machining services for complex and high-precision components.

3. What materials can Sin Ling manufacture?

We produce fittings and machined parts in brass, copper, steel, stainless steel, and aluminum. Material selection depends on customer specifications, operating pressure, corrosion resistance, and industry requirements.

4. Are your products certified for automotive or safety-critical applications?

Yes. Sin Ling holds ISO 9001, IATF 16949, and FMVSS 571.106 DOT certifications. These ensure consistent quality and compliance for safety-critical components such as air brake fittings, hydraulic connectors, and industrial pneumatic parts.

5. Do you manufacture hydraulic hose fittings?

Yes. As a hydraulic hose fittings manufacturer, Sin Ling produces hydraulic adapters, ORB/SAE threads, JIC fittings, banjo components, and custom hydraulic connectors made to customer drawings.

6. What machining capabilities do you offer?

Our factory is equipped with multi-spindle CNC machines, rotary transfer systems, and high-speed turning centers. We specialize in multi-axis machining services, enabling high-volume production with tight tolerances and consistent accuracy.

7. What is the typical lead time for production?

Lead time varies based on order quantity and product complexity. Most Standard brass fittings are typically in stocks, while custom OEM parts or complex multi-axis components may require additional engineering and tooling time.

8. Can Sin Ling support long-term supply programs for OEM customers?

Absolutely. We have decades of experience supplying long-term production programs for global OEMs, Tier-1 manufacturers, and large distributors. We offer forecasting management, safety stock planning, and stable production capacity exceeding 10 million parts per year.

9. Does Sin Ling export internationally?

Yes. We export to North America, Europe, Japan, Australia, and many other regions. Our fittings and machined components are widely used by OEMs, performance manufacturers, hydraulic integrators, and global distributors.

10. How can I request a quotation or provide drawings?

You can contact Sin Ling directly via email with product drawings, specifications, usage requirements, and annual volume. Our engineering team will review your request and provide a detailed quotation and lead time.

| CNC Model | Pfiffner | GNUTTI | MIYANO | NAKAMUNA TOME | DMG MORI | CITIZEN CINCOM L20/L32 |

| CNC Machines |

|

|

|

|

|

|

| Numbers | 5 | 1 | 15 | 2 | 2 | 25 |

|

Category |

High volume components | High volume components |

Big size components,

Forging/Casting components

|

Medium size components,

Assembly components

|

Medium size components,

Assembly components

|

Small size components |

| Raw material |

Brass Steel Zinc alloy Stainless Aluminum |

Brass Steel Zinc alloy Stainless Aluminum |

Brass Steel Zinc alloy Stainless Aluminum |

Brass Steel Zinc alloy Stainless Aluminum |

Brass Steel Zinc alloy Stainless Aluminum |

Brass Steel Zinc alloy Stainless Aluminum |

| Machining size |

RodØ45 Hex H38 |

RodØ100 | RodØ100 |

RodØ45 Hex H36 |

RodØ52 Hex H45 |

RodØ20/Ø32 |

| Application |

|

|

|

|

|

|

| Max. capacity | 100,000/day | 100,000/day | 20,000/day | 30,000/day | 20,000/day | 60,000/day |