Quality Management

Inspection process

Inspection with Contour Measuring Instrument

Size measuring

Quality Management & Inspection

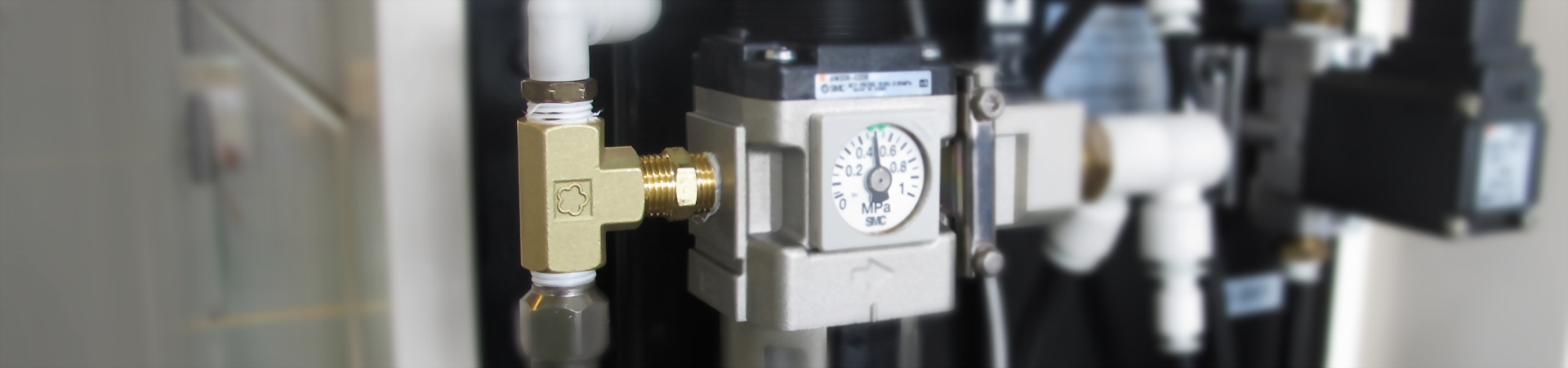

At Sin Ling, we are committed to maintaining stable, high-quality production in line with ISO 9001 international standards. Our quality assurance system covers every stage—from raw material receiving, in-process monitoring, to final inspection before shipment—ensuring consistency and full traceability across all batches.

We employ advanced inspection technologies and instruments to support real-time precision monitoring and ensure that each part meets or exceeds customer requirements.

Process Control Capability

In addition to equipment, Sin Ling integrates advanced process control systems to further enhance quality, including:

-

Tool life management systems

-

Automatic error detection mechanisms

-

Statistical process control (SPC)

-

In-line dimensional verification

These systems reduce human error, prevent defective output, and ensure production remains stable and predictable—critical for high-precision industries like automotive and hydraulic applications.

Comprehensive QC Workflow

-

Incoming Inspection: Every batch of raw material is verified upon arrival.

-

In-Process Checks: Conducted every 1–2 hours to ensure process stability.

-

Final Inspection: All outgoing products are verified against customer specs.

By combining cutting-edge equipment with strict procedural control, we deliver products that meet the most demanding quality standards while supporting continuous improvement and traceability.

| QC Inspection equipment |

|

Contour Measuring Instrument |

| Coordinate Measuring Machine |

|

Ring Gauge/Plug Gauge |

| Surface roughness measuring instrument |

|

Quick Vision Measuring Instrument |

| Height gauge |

|

Screw Thread Micrometer |

| Internal Caliper |

| Micrometer Caliper |